5356 Aluminium Welding Wire

5356 aluminum welding wire is a high-strength, corrosion-resistant alloy widely used for welding aluminum alloys with high magnesium content, such as 5XXX series aluminum. It is ideal for applications in marine environments, structural projects, and automotive manufacturing due to its excellent corrosion resistance, especially in saltwater conditions. Additionally, 5356 aluminum wire offers good weldability, making it a preferred choice for general-purpose welding of aluminum, ensuring strong and durable joints in demanding environments.

| Specifications of 5356 Aluminum Welding Wire: |

| Grade | 4043,4047,5356 etc. |

| Standard | AWS A5.10 |

| Diameter | MIG – 0.8 to 1.6 mm,TIG – 1 to 5.5 mm,Core wire – 1.6 to 6.0 |

| Surface | Bright, Cloudy |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

5356 aluminum wire Chemical Composition: |

| Grade | Al | Si | Cu | Mg | Ni | Fe | Zn | Mn | Cr | Ti |

| 5356 | Rem | 0.25 | 0.10 | 4.5-5.5 | 0.5-1.3 | 0.40 | 0.10 | 0.05-0.20 | 0.05-0.20 | 0.06-0.20 |

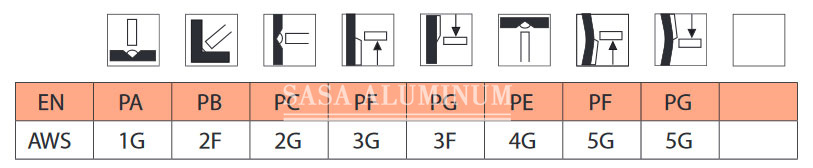

Welding positions and important items: |

1.Clean the Material: Remove oxides, dirt, and grease before welding.

2.Control Heat: Avoid overheating to prevent warping and cracking.

3.Use Proper Filler Wire: Match the filler wire to the base metal (e.g., 5356 or 4043).

4.Correct Shielding Gas: Use pure argon or an argon-helium mix.

5.Set Equipment Properly: Ensure correct polarity and welding speed.

6.Prevent Defects: Avoid porosity and cracking through proper technique and preparation.

Features of ER5356 Aluminum Welding Wire : |

1.Corrosion Resistance: It offers excellent resistance to corrosion, especially in marine and saltwater environments, making it ideal for applications in ships, boats, and offshore structures.

2.High Strength: 5356 welding wire provides a strong and durable weld, especially when used with aluminum alloys in the 5XXX series, resulting in reliable and sturdy joints.

3.Good Weldability: This wire has good welding characteristics, making it easy to work with and suitable for a variety of welding processes like MIG (GMAW).

4.Versatile Applications: Due to its combination of strength and corrosion resistance, it is used in various industries, including automotive, aerospace, and construction.

5.Aesthetic Finish: The welds produced by 5356 wire have a clean and smooth finish, which is important for visible or exposed applications.

| Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

| Why Choose Us ? |

1.With over 20 years of experience, our team of experts ensures top-notch quality in every project.

2.We adhere to stringent quality control processes to ensure every product meets the standards.

3.We leverage the latest technology and innovative solutions to deliver superior products.

4.We offer competitive pricing without compromising on quality, ensuring you get the best value for your investment.

5.We offer a comprehensive range of services to meet all your needs, from initial consultation to final delivery.

6.Our commitment to sustainability and ethical practices ensures that our processes are environmentally friendly.

| 5356 Aluminum Wire Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa aluminum’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as