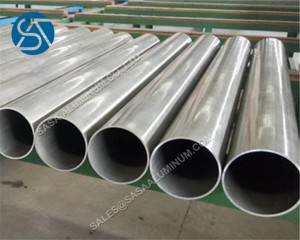

5A06 Aluminum Tube

Our 5A06 aluminum tubes offer superior strength and corrosion resistance, making them ideal for marine, aerospace, and industrial applications. With a tensile strength of 370-420 MPa and excellent elongation properties, these tubes are perfect for demanding environments.5A06 aluminum tubes are widely used in the marine industry for shipbuilding, in aerospace for aircraft components, and in industrial applications requiring high strength and corrosion resistance.

| Specifications of 5A06 aluminum pipe: |

| Grade | 2A12,2024,5A06O,5652, 5086, 5056, 5754, 6061, 6062, 6063, 5052H18, 5A06 etc. |

| Standard | GB/T 3190-2008 |

| Sizes | 1/8″ – 16″ (3mm – 2500mm) OD .020″ – 2″ (.2mm – 150mm) wall (1m-12m) Length |

| Technology |

Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | seamless, drawn and coiled Tubing |

| Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H112 |

| Surface | Anodized, Oxidation, electrophoresis coating, fluorine carbon spraying |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

| CHEMICAL COMPOSITION OF 5A06 alloy tube: |

| Grade | Al | Mg | Si | Fe | Cu | Zn | Ti | Mn | Cr |

| 5A06 | Remainder | 5.8 - 6.8max | 0.40 max | 0.40max | 0.1 |

0.20 |

0.02-0.10max |

0.5-0.8 |

- |

| 5A06 aluminum tube Mechanical Properties |

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min |

| 5A06 | 370 - 420 MPa | 260 - 320 MPa | 10-12 |

5A06 Aluminum Tube Applications: |

1.Aerospace: Aircraft structural components, aviation equipment.

2.Marine Engineering: Shipbuilding, marine equipment.

3.Transportation: Automotive parts, railway vehicles.

4.Construction: Structural components, curtain wall systems.

5.Industrial Applications: Machinery equipment, chemical equipment.

6.Sports and Recreation Equipment: Sports gear, recreational boats.

7.Power Engineering: Transmission towers and cables.

| Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

| Why Choose Us ? |

1.With over 20 years of experience, our team of experts ensures quality in every project.

2.We adhere to stringent quality control processes to ensure every product meets the standards.

3.We leverage the latest technology and innovative solutions to deliver superior products.

4.We offer competitive pricing without compromising on quality, ensuring you get the best value for your investment.

5.We offer a comprehensive range of services to meet all your needs, from initial consultation to final delivery.

6.Our commitment to sustainability and ethical practices ensures that our processes are environmentally friendly.

| 5A06 Aluminum Tube Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa aluminum’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as