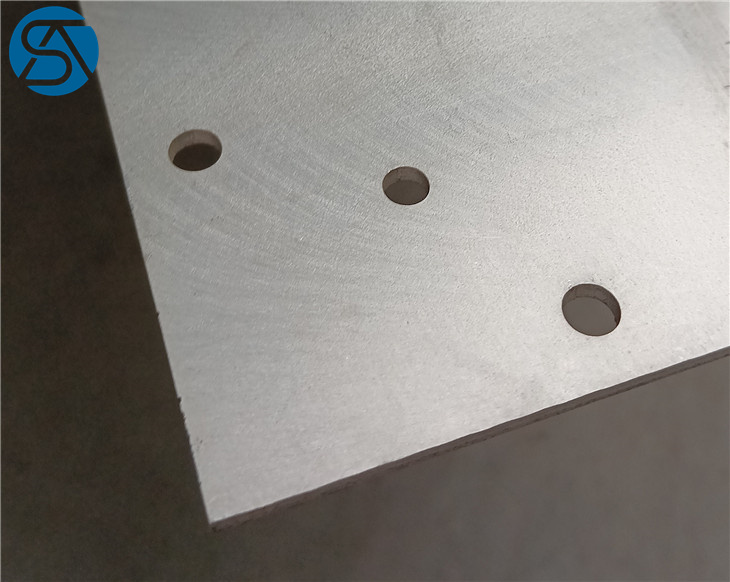

Laser Cut Perforated 6061 Aluminium Plate

| Specifications of 6061 Laser Cut Plate: |

Laser cutting perforated 6061 aluminum plates is a common manufacturing process used to create precise patterns of holes or other shapes in aluminum sheets. 6061 aluminum alloy is a versatile material known for its excellent strength-to-weight ratio, corrosion resistance, and weldability, making it suitable for various applications across industries such as aerospace, automotive, and electronics.Perforated aluminum plates find applications in various industries, including architectural design, filtration systems, decorative panels, and aerospace components.

| Standards | ASTM B209 / ASME SB209 |

| Thickness | 0.2-50mm |

| Width | 100-2600mm |

| Length | 500-10000mm |

| Temper | O,H12,H14,H16,H18,H19,H22,H24 |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

| Provide Classification Society | American Bureau of Shipping (ABS),Lloyd's Register (LR),Bureau Veritas (BV),Germanischer Lloyd (GL),Det Norske Veritas (DNV),Nippon Kaiji Kyokai (NK),Korean Register of Shipping (KR),Registro Italiano Navale (RINA),China Classification Society (CCS) |

| Technology | Cutting,Perforated |

| Laser cutting perforating aluminum plates Types : |

| 6061 Perforated Sheet Equivalent Grades : |

| Grade | UNS | USA | WNR | EN | DIN | ISO | BS |

| 6061 | A96061 | AA6061 | 3.3211 | AW-AlMg1SiCu

EN AW-6061 |

AlMgSiCu | AlMg1SiCu | HE20 |

| 6061 Aluminium Plate Chemical Composition: |

| Grade | Fe | Si | Mg | Mn | Cu | Zn | Ti | Cr | Al | Others |

| 6061 | 0.7 | 0.4-0.8 | 0.8-1.2 | 0.15 | 0.15-0.4 | 0.25 | 0.15 | 0.15-0.35 | Remainder | 0.005/0.15 |

| Mechanical Properties of 6061 Aluminum Plates & Sheets: |

| Grade | Density | Tensile Strength | Hardness Brinell | Hardness Rockwell | Yield Strength | Fatigue Strength | Shear Strength |

| 6061 | 2.7 g/cc | 310MPa | 95 | B60 | 276Mpa | 96.5 MPa | 207 MPa |

| What are the differences between laser cutting and plasma cutting? |

Plasma cutting machine is a kind of thermal cutting equipment. The main working principle is compressed air as the main body and high-temperature and high-speed plasma arc as the heat source. It locally melts the metal being cut and blows away the melted metal with high-speed airflow at the same time. Create a narrow slit. Plasma cutting machines can cut various metal materials such as stainless steel, iron, aluminum, and copper with fast cutting speed, narrow slits, and smooth cuts. Plasma cutting machines are generally used in the construction, installation and maintenance of machinery and metal structures.

Laser cutting machines use high-power and high-density laser beams to scan the surface of materials. They can heat the materials to thousands or even tens of thousands of degrees Celsius in a short time, melt or vaporize the materials, and then use high-pressure gas to melt or vaporize the materials. Other materials are blown away from the cuts. Laser cutting uses an invisible beam to replace the traditional mechanical knife. The laser cutting speed is fast and the incision is smooth. Generally, no post-processing is required. The cutting is less affected by heat and the plate deformation is small.

The difference in cutting accuracy is that plasma cutting accuracy can reach within 1mm, while laser cutting accuracy can reach within 0.22mm. In terms of cost, plasma cutting machines are cheaper than laser cutting machines. In terms of processing accuracy, plasma cutting is equivalent to rough processing, and laser cutting is equivalent to fine processing.

| How to choose the lamination of aluminum cutting plate? |

In order to ensure the surface finish of metal materials, many metal products are coated. Aluminum plates use protective films, generally ordinary blue films and laser films. Ordinary blue films are cheap, but they need to be torn off during laser cutting because the cutting gas penetrates into the plate and protective film during the laser cutting process, causing blistering problems. Large bubbles at the laser cutting head may cause uncontrolled movement of the plate, ultimately causing serious damage to the plate. When the cutting distance is very close, the gas pressure is concentrated on a smaller surface area, which is more likely to cause blistering problems. If a film is needed to protect the product during laser cutting, laser film should be selected. Compared with ordinary films, laser films have strong enough viscosity and a stretching effect.

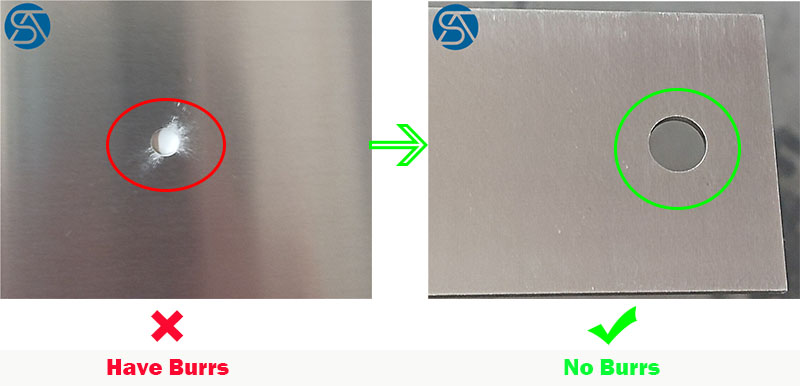

| How can burrs be reduced and eliminated during the aluminum cutting process? |

To reduce and eliminate burrs during the aluminum cutting process, the following methods can be used: choosing the right cutting tools and equipment, optimizing cutting parameters, using laser or water jet cutting, performing secondary processing such as deburring and chamfering, and selecting appropriate aluminum materials. These methods can significantly improve cutting results, enhancing the quality and efficiency of the workpieces.

| Laser cutting offers several advantages for perforating aluminum plates, including: |

1.Precision: Laser cutting allows for very precise cuts and hole patterns, enabling intricate designs and tight tolerances to be achieved.

2.Versatility: Laser cutting can create a wide range of hole sizes, shapes, and patterns, depending on the requirements of the application.

3.Speed: Laser cutting is a fast and efficient process, capable of perforating aluminum plates quickly and accurately.

4.Clean edges: Laser cutting produces clean, burr-free edges, minimizing the need for additional finishing processes.

| Our Services: |

1.Quenching and tempering

2.Vacuum heat treating

3.Mirror-polished surface

4.Precision-milled finish

5.CNC machining

6.Precision drilling

7.Cut into smaller sections

8.Achieve mold-like precision

| Laser Cut Perforated Aluminium Plate Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa aluminum's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,