7055 Aluminum Plate

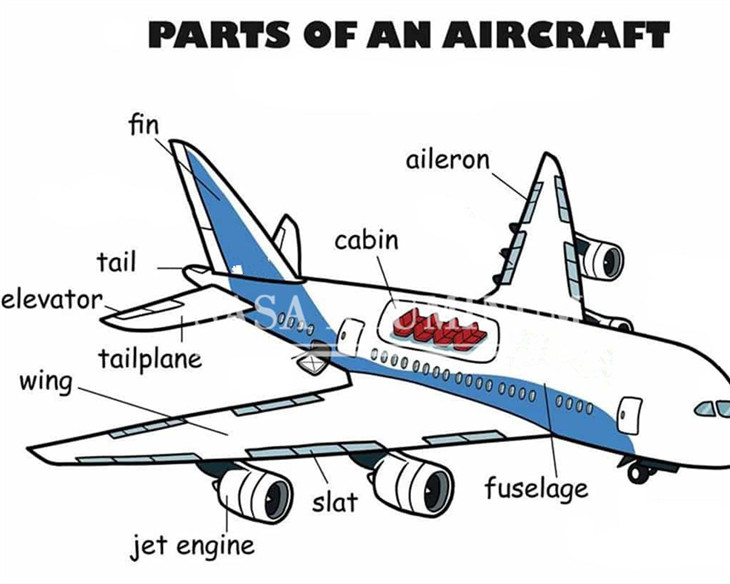

The 7055 aluminum plate is a high-strength, aerospace-grade alloy known for its excellent strength-to-weight ratio, fatigue resistance, and good corrosion resistance. It is widely used in aircraft structures and other high-performance applications where durability and strength are critical. With its exceptional mechanical properties, 7055 aluminum plate is ideal for demanding industries like aerospace and military.

| Specifications of 7055 Aluminum Plate: |

| Grade | 1050, 1060, 1100, 1235, 3003, 3004, 3105, 5052, 5754, 6061 etc. |

| Standard | ASTM B209,GB/T3190 |

| Temper | T7651,T7751 |

| Thickness | 3.0mm-200mm |

| Width | 500-2600mm |

| Length | to clients’ requirement |

| Certificate of Classification | Classification Society (CCS), American Classification Society (ABS), French Classification Society (BV), British Classification Society (LR) Classification society certification. |

| Coating finish | PVDF, POLYESTER(PE) |

| Surface | Bright, polished, hair line, brush,etc. |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

Chemical composition of 7055 aluminum aerospace plate: |

| Grade | Al | Mg | Mn | Cr | Fe | Si | Cu | Zn | Ti | Zr |

| 7055 | Rem | 1.8-2.3 | 0.50 | 0.04 | 0.15 | 0.10 | 2.0-2.6 | 7.6-8.4 | 0.06 | 0.05-0.25 |

Mechanical properties of 7055 aluminum plate: |

| Grade | Tensile strength | Yield strength | Elongation |

| 7055 | 600-680MPa | 480-510 MPa | 6%-7% |

| Applications of 7055 Aluminum Plate : |

Various aluminum alloys, including 7055, are crucial in aerospace, military, and high-performance applications due to their strength, fatigue resistance, and durability. Notable alloys such as 7075, 2024, 6061, 7475, 6082, and 5083 each offer unique properties, making them suitable for critical structures like aircraft components, military equipment, and marine applications. These alloys provide a balance of performance characteristics that meet the demanding requirements of their respective industries.

| Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

| Why Choose Us ? |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. Provide SGS TUV report.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

7.Provide one-stop service.

| 7055 Aluminum Sheet Manufacturers Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa aluminum’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as