7150 Aluminum Sheet Plate

The 7150 aluminum plate is a high-strength, aerospace-grade alloy primarily composed of aluminum and zinc, designed for applications that demand exceptional strength and resistance to stress corrosion cracking. It is commonly used in aerospace, military, and high-performance industries for structural components, including aircraft wings, fuselage, and critical load-bearing parts. The alloy is known for its excellent fatigue strength, lightweight properties, and high tensile strength, making it ideal for demanding environments. Available in various thicknesses and temper conditions, such as T7651, 7150 aluminum plate offers superior performance in both high-stress and corrosive environments.

| Specifications of 7150 Aluminum Plate: |

| Grade | 1050, 1060, 1100,3003, 3004, 3105, 5052, 5754, 6061 etc. |

| Standard | ASTM B209 |

| Temper | T6151,T7751 |

| Thickness | 3.0mm-200mm |

| Width | 500-2600mm |

| Length | to clients’ requirement |

| Certificate of Classification | Classification Society (CCS), American Classification Society (ABS), French Classification Society (BV), British Classification Society (LR) Classification society certification. |

| Coating finish | PVDF, POLYESTER(PE) |

| Surface | Bright, polished, hair line, brush,etc. |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

Chemical composition of 7150 aluminum aircraft plate: |

| Grade | Al | Mg | Mn | Cr | Si | Cu | Zn |

| 7150 | Rem | 1.9-2.6 | 0.15-0.40 | 0.18-0.28 | 0.10 | 1.2-2.0 | 5.6-6.3 |

Mechanical properties of 7150 aluminum plate: |

| Grade | Temper | Tensile strength | Yield strength | Elongation |

| 7150 | T7751 | 570MPa | 505MPa | 7% |

| T6151 | 495MPa | 435Mpa | 8% |

7150 Aviation Aluminum Sheet Characteristics : |

The 7150 aircraft aluminum sheet is a high-performance, lightweight, and corrosion-resistant alloy designed for aerospace applications. Key features of this material include:

1.Exceptional Strength: With a tensile strength of over 570 MPa (82,700 psi), the 7150 aluminum sheet surpasses traditional alloys like 2024 and 7075 in terms of strength, making it ideal for high-stress environments.

2.Lightweight: Boasting a low density of about 2.8, 7150 aluminum is significantly lighter than steel, which helps reduce the overall weight of aircraft and enhances fuel efficiency while increasing payload capacity.

3.Superior Corrosion Resistance: The alloy's composition, which includes copper and magnesium, provides excellent resistance to corrosion, enabling it to withstand harsh operating conditions for extended periods, especially in aerospace and military environments.

4.Ease of Processing: The 7150 aluminum sheet can be easily processed through both cold and hot working techniques, allowing for the efficient manufacturing of complex and precise aerospace components.

5.Weldability: This material is highly compatible with various welding methods, including argon arc welding and laser welding, making it suitable for easy assembly, repair, and part replacement in aircraft structures.

7150 aerospace aluminum sheet application: |

7150 aluminum sheet is widely used in various demanding applications, particularly in the aerospace and defense industries, due to its high strength, lightweight properties, and excellent corrosion resistance. Some key applications include:

1.Aerospace Structures:7150 aluminum is commonly used for critical aircraft components such as wings, fuselage, and tail sections. Its high strength-to-weight ratio makes it ideal for reducing overall aircraft weight while maintaining structural integrity under high stress.

2.Aircraft Frames and Load-Bearing Parts:The alloy is often used for parts of aircraft that are subject to heavy loads, such as landing gear components, frames, and structural beams, where strength and weight savings are paramount.

3.Missile and Defense Components:In military applications, 7150 aluminum is used for high-performance components like missile bodies, launch structures, and other defense-related parts that require materials with superior mechanical properties and resistance to harsh environmental conditions.

4.Spacecraft Structures:The alloy's high strength and lightweight properties make it suitable for use in space vehicles and satellite structures, where reducing weight is crucial for fuel efficiency and overall performance.

5.Marine Applications:Due to its corrosion resistance, 7150 aluminum is also used in marine environments for boat hulls, underwater structures, and other maritime applications where resistance to saltwater corrosion is essential.

6.High-Performance Racing Vehicles:The automotive and motorsport industries also benefit from the alloy’s strength and lightness, with 7150 aluminum used in the construction of racing car frames, suspension parts, and wheels.

7.Transportation and High-Speed Vehicles:7150 aluminum is utilized in high-speed trains and other transportation vehicles where a combination of strength, reduced weight, and high durability is needed.

8.Precision Engineering:The alloy’s ability to be easily processed makes it a preferred material for complex, precision-engineered components used in a variety of high-tech industries, including electronics, robotics, and medical devices.

| Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Ultrasonic test

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Impact analysis

10. Metallography Experimental Test

| Why Choose Us ? |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. Provide SGS TUV report.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

7.Provide one-stop service.

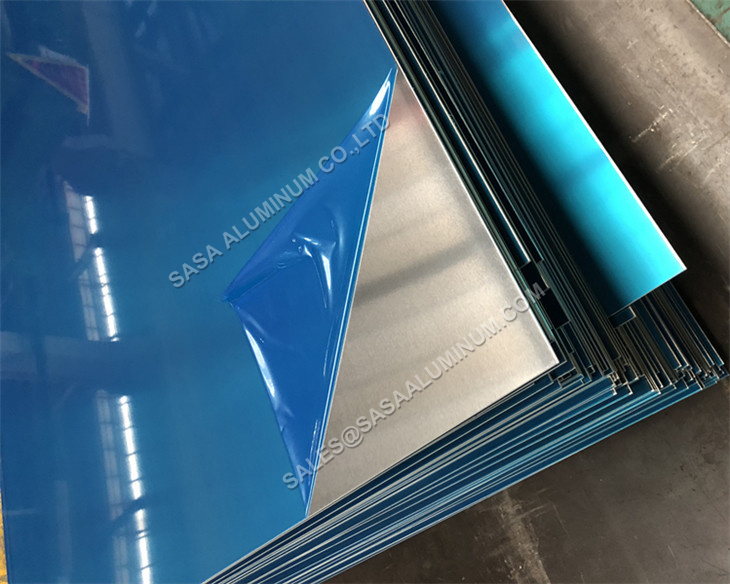

| Aluminum Sheet Manufacturers Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa aluminum’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as