ER4043 Aluminum Welding Wire

ER4043 aluminum welding wire is a premium-grade Al-Si5 alloy wire containing approximately 5% silicon, engineered for superior weldability, excellent fluidity, and enhanced crack resistance. It produces smooth, bright weld beads with minimal spatter, making it ideal for both MIG and TIG welding processes.This alloy is widely compatible with a range of aluminum base metals, particularly 6xxx series alloys like 6061, 6063, and 6082, as well as 3003 and 5052. ER4043 is the go-to choice for general aluminum fabrication, automotive repair, HVAC components, structural frames, and aluminum parts that require good corrosion resistance and finish.

| Specifications of 4043 Aluminum Welding Wire: |

| Grade | 4043,4047,5356 etc. |

| Standard | AWS A5.10 |

| Diameter | MIG – 0.8 to 1.6 mm,TIG – 1 to 5.5 mm,Core wire – 1.6 to 6.0 |

| Surface | Bright, Cloudy |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

ER4043 aluminum wire Chemical Composition: |

| Grade | Al | Si | Cu | Mg | Zn | Mn | Ti |

| ER4043 | Rem | 4.5-6.0 | 0.30 | 0.05 | 0.10 | 0.05 | 0.20 |

Typical Welding Parameters for ER4043 Aluminum Welding Wire: |

| Welding Process | Wire Diameter | Voltage (V) | Amperage (A) | Shielding Gas |

| MIG (GMAW) | 0.8 mm (0.030") | 16–20 V | 60–140 A | 100% Argon |

| MIG (GMAW) | 1.0 mm (0.040") | 17–22 V | 80–140 A | 100% Argon |

| MIG (GMAW) | 1.2 mm (0.045") | 18–24 V | 100–220 A | 100% Argon |

| MIG (GMAW) | 1.6 mm (1/16") | 20–26 V | 140–300 A | 100% Argon |

| TIG (GTAW) | 1.6 mm (1/16") | - | 70–150 A | 100% Argon |

| TIG (GTAW) | 2.4 mm (3/32") | - | 100–200 A | 100% Argon |

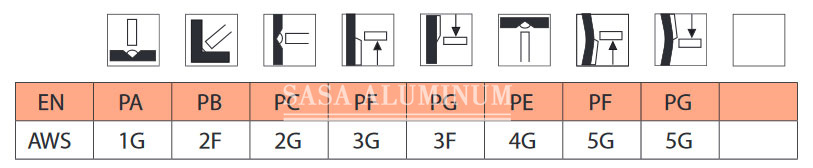

Welding positions and important items: |

1.Clean the Material: Remove oxides, dirt, and grease before welding.

2.Control Heat: Avoid overheating to prevent warping and cracking.

3.Use Proper Filler Wire: Match the filler wire to the base metal.

4.Correct Shielding Gas: Use pure argon or an argon-helium mix.

5.Set Equipment Properly: Ensure correct polarity and welding speed.

6.Prevent Defects: Avoid porosity and cracking through proper technique and preparation.

Applications of ER4043 Aluminum Welding Wire : |

•Automotive Industry:For welding aluminum car parts, heat exchangers, radiators, and aluminum frames.

•General Aluminum Fabrication:Used in the assembly of aluminum structures, enclosures, and light-duty frames.

•HVAC & Refrigeration:Suitable for aluminum heat exchangers, air conditioning components, and piping systems.

•Shipbuilding and Marine Equipment:For non-structural aluminum components that require good corrosion resistance.

•Bicycle and Motorcycle Frames:Ideal for joining aluminum tubing with smooth weld beads.

•Household Appliances & Furniture:Applied in aluminum shelving, fixtures, and consumer product components.

•Aluminum Casting Repair:Excellent for repair welding of cast aluminum parts and die-cast components.

| Quality Assurance (including both Destructive and Non-Destructive) : |

1.Raw Material Control

2.Chemical Composition Inspection

3.Dimensional Accuracy

4.Surface Quality

5.Weldability Testing

6.Packaging Inspection

7.Quality Certification

| Why Choose Us ? |

1.With over 20 years of experience, our team of experts ensures top-notch quality in every project.

2.We adhere to stringent quality control processes to ensure every product meets the standards.

3.We leverage the latest technology and innovative solutions to deliver superior products.

4.We offer competitive pricing without compromising on quality, ensuring you get the best value for your investment.

5.We offer a comprehensive range of services to meet all your needs, from initial consultation to final delivery.

6.Our commitment to sustainability and ethical practices ensures that our processes are environmentally friendly.

| ER4043 Aluminum Wire Packing: |

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Sasa aluminum’s pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as